Cathodic Protection

Concrete will, under most circumstances provide a highly alkaline environment in which steel reinforcement will be protected from corrosion by the formation of a passive oxide layer. This passive oxide layer can in time be compromised, primarily due to the effects of carbonation or chlorides, leading to corrosion of the steel reinforcement, thus putting the long-term durability of the structure into question.

With the annual cost of corrosion to the UK economy rising to billions each year, Cathodic Protection (CP) Systems have become increasingly essential and are frequently specified as the primary solution for preserving reinforced concrete structures. CP is an electrochemical method of corrosion control that can be applied to submerged metallic materials, often utilised for the prolonged preservation of the steel reinforcement within concrete structures. Once installed and activated, CP can significantly reduce structural life cycle costs that are usually associated with traditional repair programmes.

As full members of the Corrosion Prevention Association (CPA), APA Concrete Repairs Ltd have consistently provided solutions that are unique to the needs of our clients’ structures for over 17 years. Our services consist of the study, design, installation and maintenance of corrosion prevention systems for new structures, as well as the repair and protection of previously installed systems. Our engineers are certified by the Institution of Corrosion and work closely with our clients in order to design the best suited and most cost-effective corrosion prevention/cathodic protection solutions for projects of all scopes.

APA Concrete Repairs Ltd are vastly experienced supply & installation contractors of multiple Cathodic Protection Systems and associated Corrosion Prevention Systems, including:

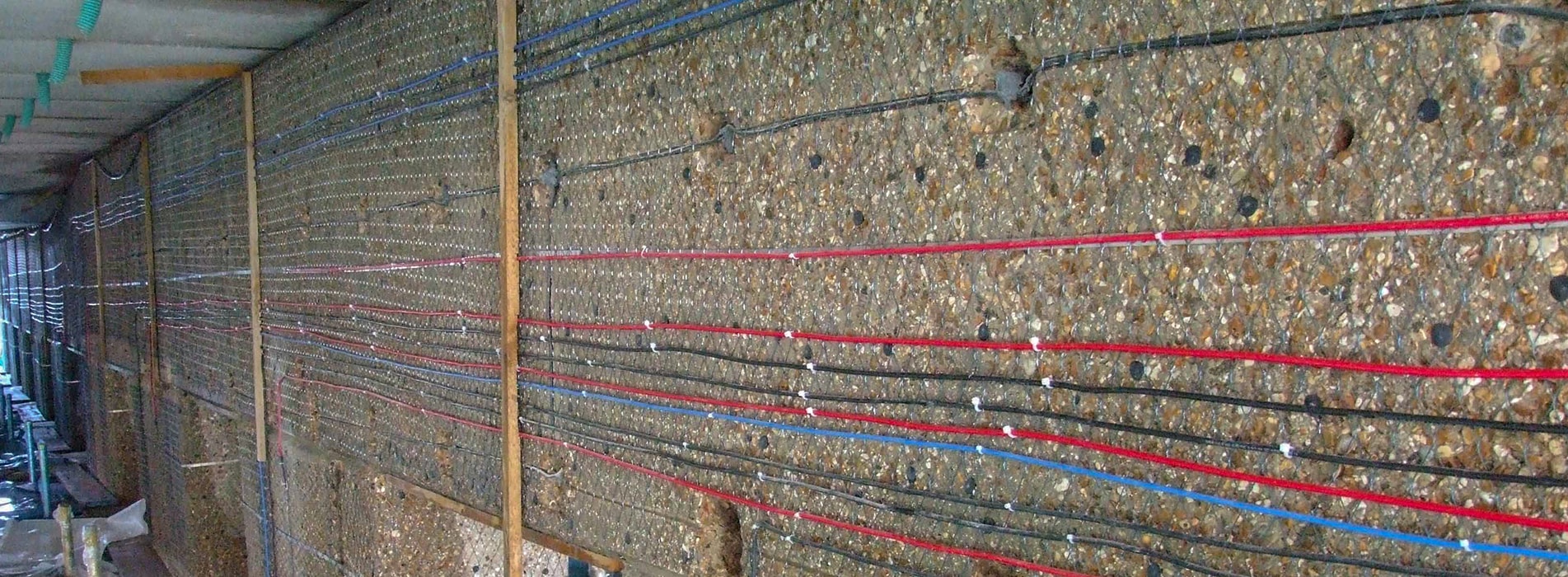

Impressed Current Cathodic Protection (ICCP)

ICCP Systems are corrosion control methods which produce a powerful external current to suppress natural electrochemical activity by supplying a controlled amount of DC current to submerged surfaces, using zinc reference anodes and metal oxide anodes. The electrical current is continuously monitored and regulated by the system itself to prevent the electrochemical action of galvanic corrosion before it can begin. Once installed and activated, ICCP systems can provide upwards of 30 years corrosion protection to a given structure.

Hybrid Anode Cathodic Protection (HACP)

Hybrid Anode CP Systems are designed to provide an initial charge, sufficient to arrest corrosion and supply an adequate current to maintain passivity for the remainder of a structures service life. These systems combine the power of traditional electrochemical systems to arrest corrosion activity with the simplicity and low maintenance requirements of galvanic technologies. They eliminate the need for permanent power supplies and therefore the associated maintenance costs, as well as reduce access requirements for their installation and monitoring.

Galvanic Cathodic Protection (GCP)

Galvanic CP Systems are corrosion prevention methods that utilise electrochemical means to protect a base material from corrosion, done so through the use of a sacrificial anode, which is more electrochemically reactive than the protected material and therefore corrodes before this material. This corrosion protection method does not rely on external electrical sources, therefore making it one of the simpler and more commonly employed forms of cathodic protection. Once installed and activated, Galvanic anodes can provide upwards of 15 years corrosion protection to a given structure.

Thermal Arc Spray (TAS)

Thermal Spray Coatings are a highly cost-effective method of protecting a given substrate from corrosion or wear, and as a result extending the life cycle/service performance and reducing future maintenance costs for the substrate in question. Anode coatings can be applied to a large surface area in a relatively short space of time with minimal disturbance to the reinforced concrete structure. APA Concrete Repairs Ltd are experienced supply & installation contractors of Thermal Arc Spray and one of very few contractors in the UK who offer this service. Contact us for further information and enquiries.